Building the Hengkai brand and walking at the forefront of the pyrite sub industry

- Home

- About Us

-

Products

Products

- Special Copper Removal Agent Series for Recycled Lead Smelting (CTJ)

- Dust-free Molybdenum-containing Iron Sulfide Series (WHML) for Resin Grinding Wheel

- Iron sulfide series for resin grinding wheel (LHT)

- Polymer Molybdenum-containing Abrasive Series (GFZ) for Resin Grinding Wheel

- Special Sulphurizer Series for Foundry Industry (ZLJ)

- Iron-sulfur alloy series for steel mills

- Special autotrophic denitrification to nitrogen new material series for sewage treatment

- Special sulfur iron denitrification filler series for constructed wetland

- Special iron sulfide series for brake pads

- Wear-resistant floor special tin titanium alloy sand series

- Pyrite, Pyrite Series

- Molybdenum Series Products

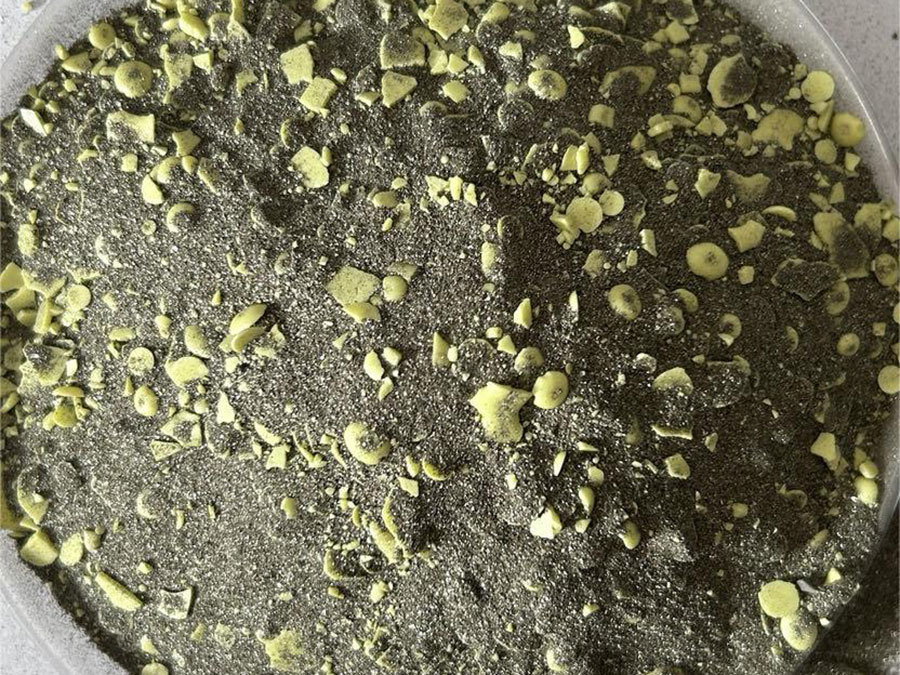

- Anti-corrosion seasoning series micaceous iron oxide

- Other Series Products

Special Copper Removal Agent Series for Recycled Lead Smelting (CTJ) Dust-free Molybdenum-containing Iron Sulfide Series (WHML) for Resin Grinding Wheel Iron sulfide series for resin grinding wheel (LHT) Polymer Molybdenum-containing Abrasive Series (GFZ) for Resin Grinding Wheel Special Sulphurizer Series for Foundry Industry (ZLJ) Iron-sulfur alloy series for steel mills Special autotrophic denitrification to nitrogen new material series for sewage treatment Special sulfur iron denitrification filler series for constructed wetland Special iron sulfide series for brake pads Wear-resistant floor special tin titanium alloy sand series Pyrite, Pyrite Series Molybdenum Series Products Anti-corrosion seasoning series micaceous iron oxide Other Series Products Marketing and service - Solution

- Advantages

- Service

-

News

- Contact

- Chinese

Lead smelting industry

Foundry industry

Abrasives industry

Sewage treatment industry

Constructed wetland filler

Friction industry (brake pads)

Solution for anti-corrosion pigment filling industry

Anti corrosion pigments and fillers mainly play a role in chemical and physical rust prevention in anti-corrosion coating systems: chemical rust prevention such as red lead and zinc chromium yellow, and physical rust prevention such as mica and glass flakes. It is also useful to use carbon black, mica iron oxide, etc. to shield the damage of sunlight and ultraviolet rays to the paint film; Adjust the pigment volume concentration with talcum powder, precipitated barium sulfate, etc. to improve the adhesion of the paint film; Adjusting the rheological properties of coatings with gas-phase silica; Using aluminum powder to improve the heat resistance of coatings. Among them, the red lead and zinc chromium yellow added in the chemical rust prevention method are toxic products, causing serious environmental pollution.

联系我们

-

-

Special Copper Removal Agent Series for Recycled Lead Smelting (CTJ)

-

Dust-free Molybdenum-containing Iron Sulfide Series (WHML) for Resin Grinding Wheel

-

Polymer Molybdenum-containing Abrasive Series (GFZ) for Resin Grinding Wheel

-

Special autotrophic denitrification to nitrogen new material series for sewage treatment

-

Special sulfur iron denitrification filler series for constructed wetland

-

Special Copper Removal Agent Series for Recycled Lead Smelting (CTJ)展开收缩

Dust-free Molybdenum-containing Iron Sulfide Series (WHML) for Resin Grinding Wheel展开收缩

Iron sulfide series for resin grinding wheel (LHT)展开收缩

Polymer Molybdenum-containing Abrasive Series (GFZ) for Resin Grinding Wheel展开收缩

Special Sulphurizer Series for Foundry Industry (ZLJ)展开收缩

Iron-sulfur alloy series for steel mills展开收缩

Special autotrophic denitrification to nitrogen new material series for sewage treatment展开收缩

Special sulfur iron denitrification filler series for constructed wetland展开收缩

Special iron sulfide series for brake pads展开收缩

Wear-resistant floor special tin titanium alloy sand series展开收缩

SAF Coolest v1.3.1.1 设置面板 BXESX-AHXX-SZSFE-ZWS

无数据提示

Sorry, the current column has no content for the time being.!

You can view other columns or returnHome Page